stainless steel crystallization reactor manufacturer

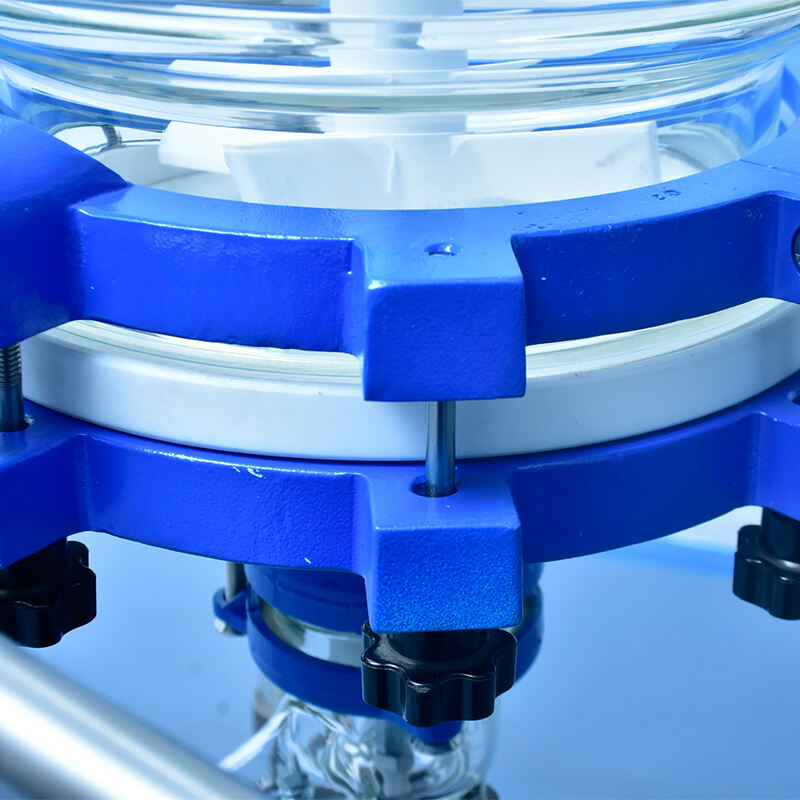

The stainless steel crystallization reactor manufacturer specializes in crafting high-quality reactors designed for the precise control of crystallization processes. These reactors are engineered to facilitate the transformation of substances from a liquid to a solid state through the controlled formation of crystals. The main functions include heating, cooling, and maintaining a stable environment for crystal growth. Technological features such as advanced PID control systems, high-grade stainless steel construction, and efficient stirring mechanisms ensure optimal performance and longevity. Applications span across pharmaceuticals, chemicals, and food industries where controlled crystallization is crucial for product purity and quality.