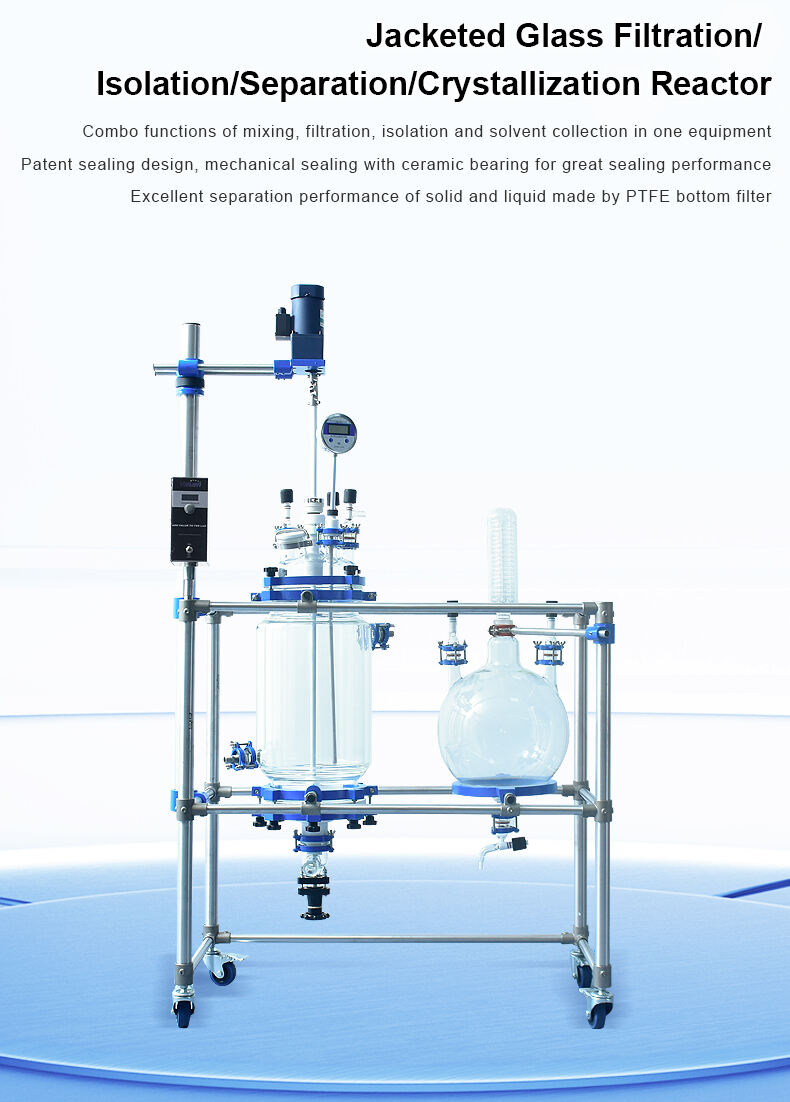

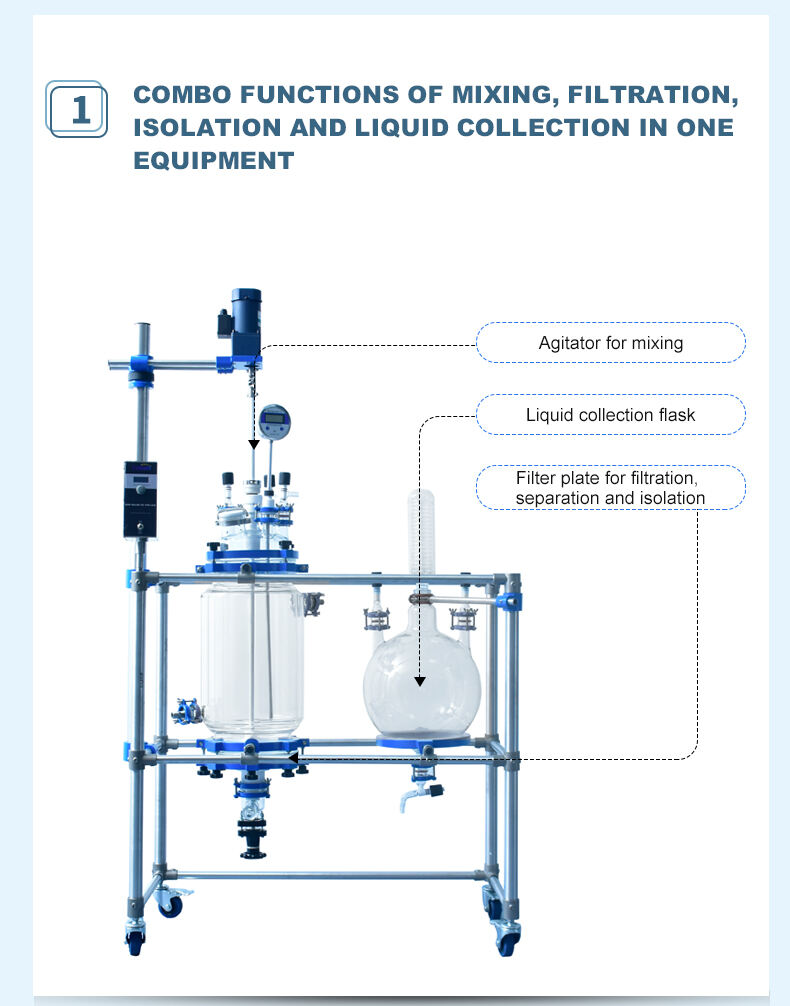

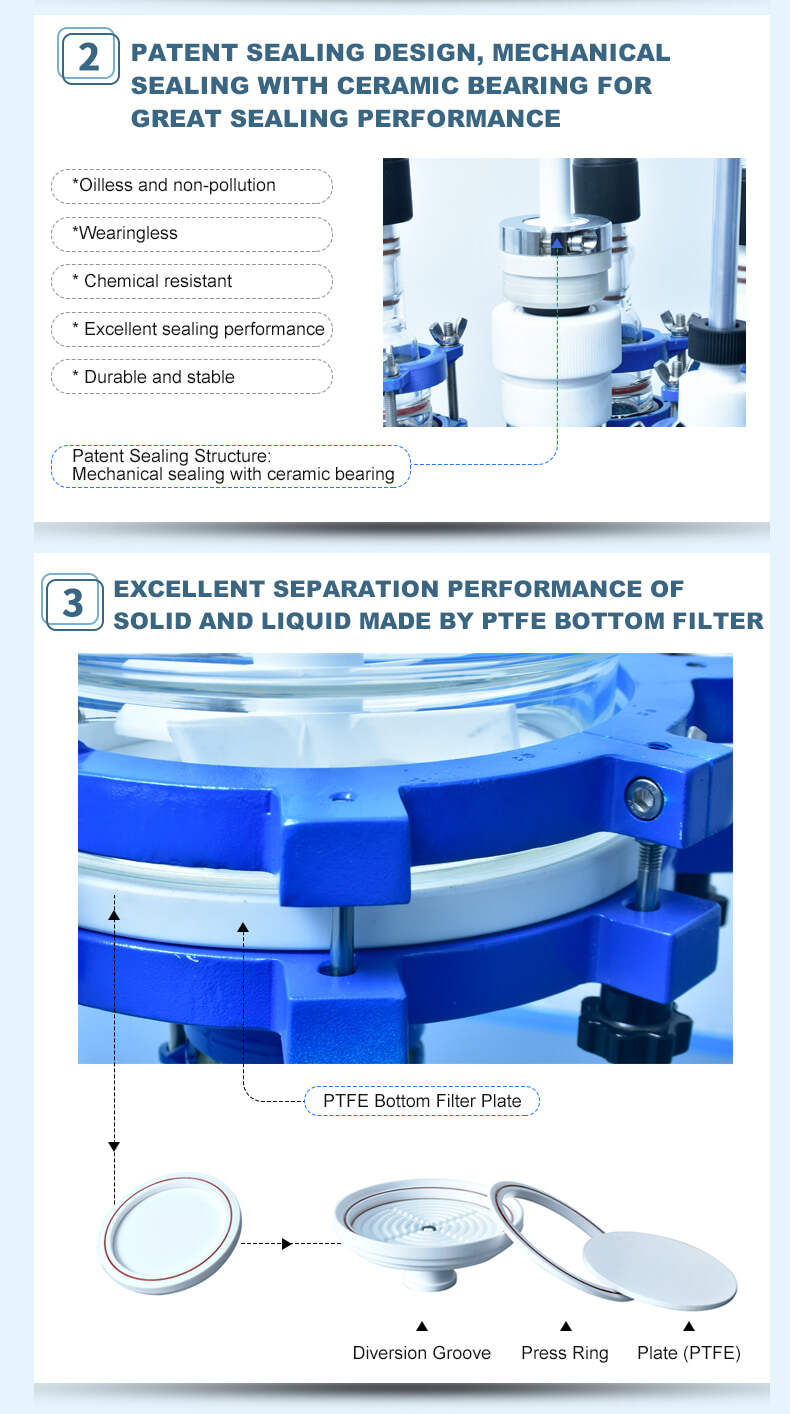

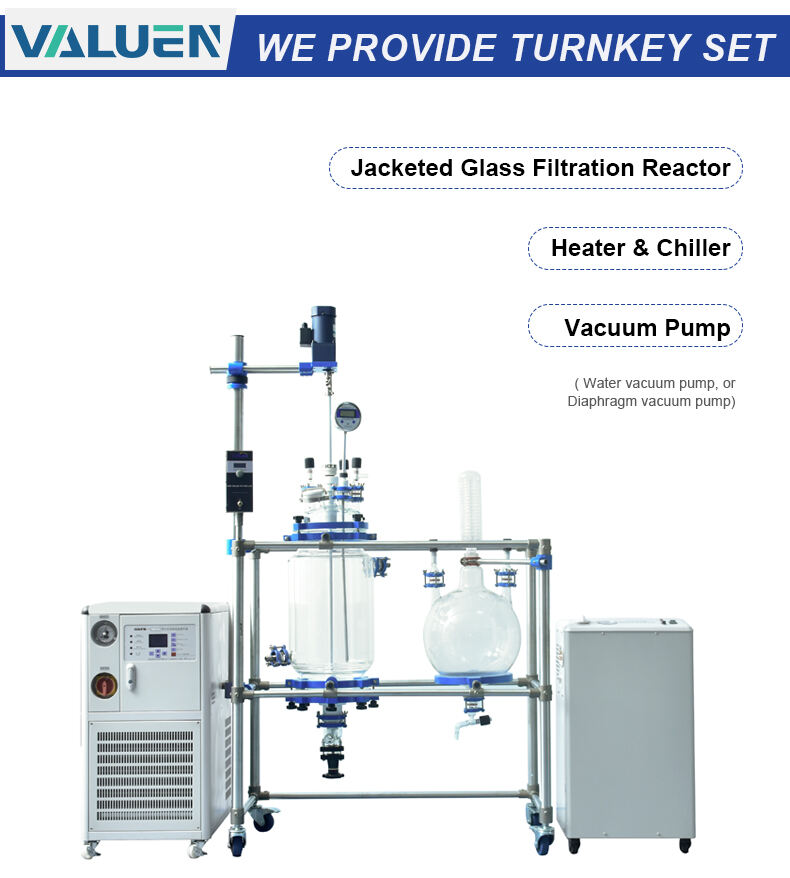

Lasikristallisointifilterireaktori on keskeinen laitteisto, joka on suunniteltu kontrolloitujen kristallisointiprosessien toteuttamiseen kemian, lääketeollisuuden ja elintarviketeollisuudessa. Korkealaatuisesta borosilikaattikallasta valmistettu se tarjoaa erinomaisen kemiallisen vastustuskykyä, läpinäkyvyyttä ja lämpöiskunestehottumusta, jolloin operaattorit voivat seurata tarkasti kiteytysalaa. Järjestelmässä on useita tukivälineitä, kuten yhdistelmälämmitin ja -jäähdytin tarkkaan lämpötilan säätämiseen, kondensaattorin kiertokulutusjäähdytin ja tyhjiöpumppu optimaalisten kiteytysaineiden ylläpitämiseksi. Lasikristallisointireaktorin kapasiteetti on 10-100 litraa ja se soveltuu ihanteellisesti sekä pienissä laboratorioissa että suurissa teollisissa prosesseissa, jolloin varmistetaan laadukas kristallisointi ja lopputuotteen puhtaus.