Paitalasilliset lasireaktorit: Äärimmäinen korroosionkestävyysratkaisu

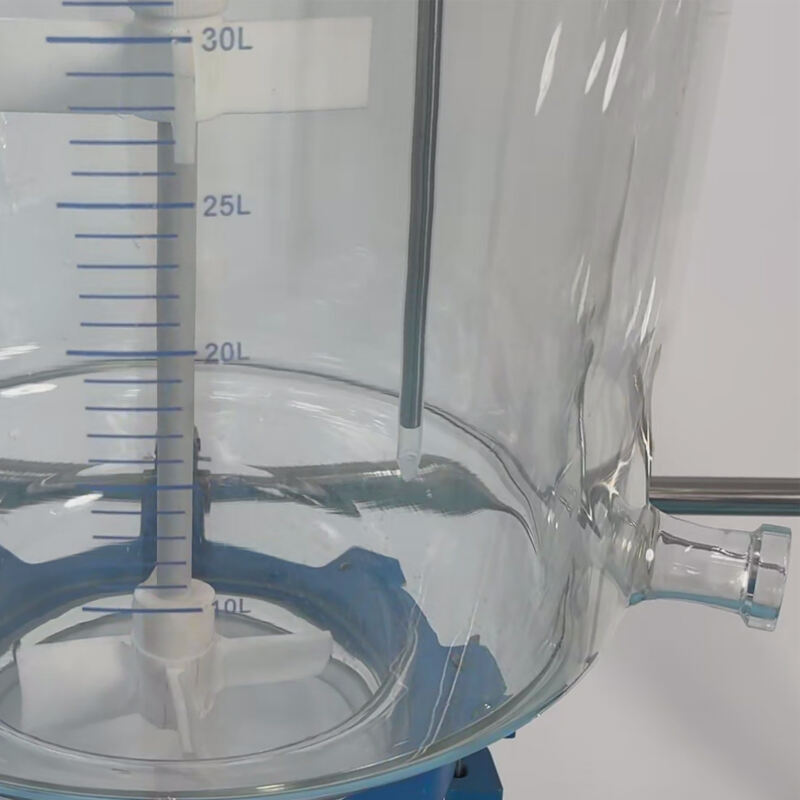

Mikä on pukeutuva lasireaktori? Pukeutuvat lasireaktorit ovat oleellisesti reaktioastioita, jotka on valmistettu lasista ja joissa on ulkoinen puku, jonka avulla lämpötiloja voidaan hallita tarkasti. Puvun rakenne mahdollistaa kuumien tai kylmien nesteiden kiertämisen reaktorin ympärillä, mikä mahdollistaa reaktion lämpötilan tehokkaan säätämisen.

Näytä lisää