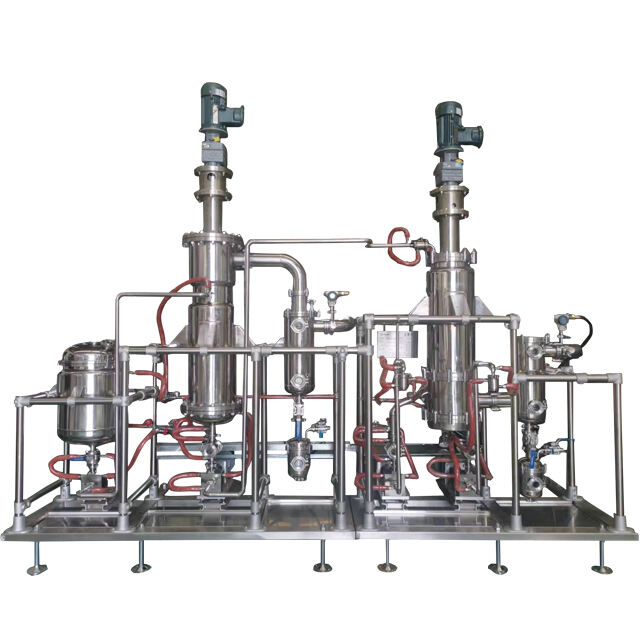

distillatio film delens

Distillatio pelliculae delens est technicae modernae ars ad separationem materiarum caloris sensibilis, praebens efficientem et lenem modum ad purgandum liquida. In suo corde, haec technologia operatur per extendendum tenuem pelliculam liquidi super superficiem calefactam, ubi evaporatio celeriter fit et vapores deinde condensantur ad productum purgatum obtinendum. Praecipuae functiones includunt concentrationem, purificationem, et recuperationem productorum altissimi valoris. Technologicae notae, ut systema continuae alimentorum, praecisa temperie moderatio, et usus mechanismi tergentis ad aequam pelliculam conservandam, altae fructus et constans qualitas curant. Applicationes per pharmaceutica, cibi processus, et chemica specialia extenduntur, ubi integritas producti servanda est praecipua.