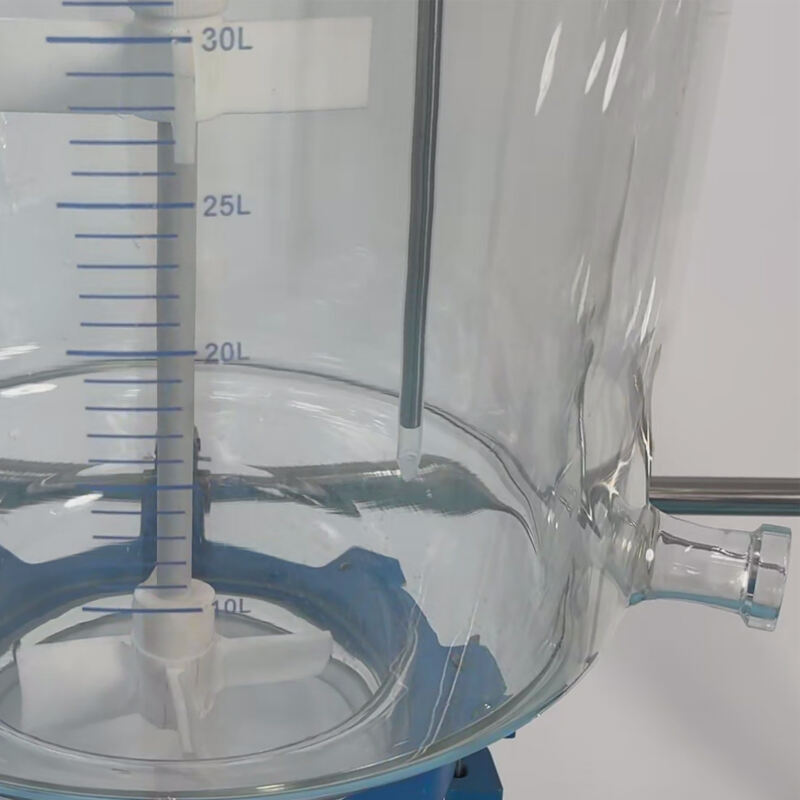

chemical reactor

A chemical reactor is a key piece of equipment in the chemical industry, designed to contain and facilitate chemical reactions. Its main functions include the transformation of reactants into desired products under controlled temperature, pressure, and reaction time conditions. Technological features of chemical reactors vary depending on their design, but typically include a sturdy construction that can withstand harsh conditions, precision engineering for accurate control of process variables, and optimized geometry for efficient mixing and heat transfer. These reactors find applications across various sectors such as pharmaceuticals, petrochemicals, and waste treatment, where they play a crucial role in producing everything from medications to fuels.