chemical reactor for stainless steel

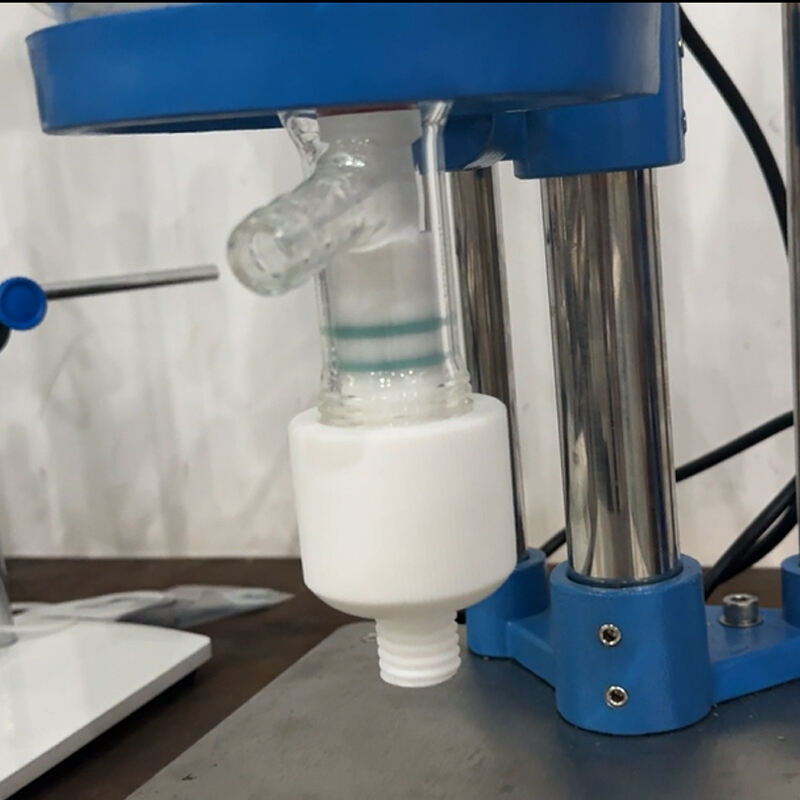

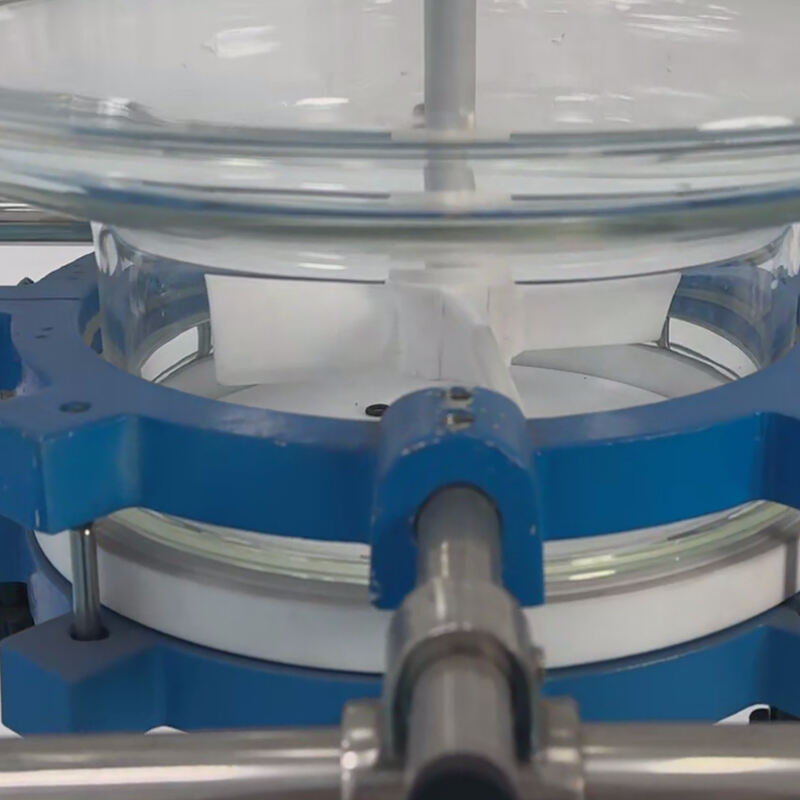

The chemical reactor for stainless steel is a precision-engineered vessel designed to facilitate controlled chemical reactions. Its main functions include mixing, heating, cooling, and containment of chemical processes, which are crucial for the manufacturing of various products. The reactor boasts technologically advanced features such as a corrosion-resistant stainless steel construction, superior thermal properties, and a design that allows for both batch and continuous processing. These features make it highly adaptable for use in pharmaceuticals, petrochemicals, food processing, and other industries where hygiene and material integrity are paramount.