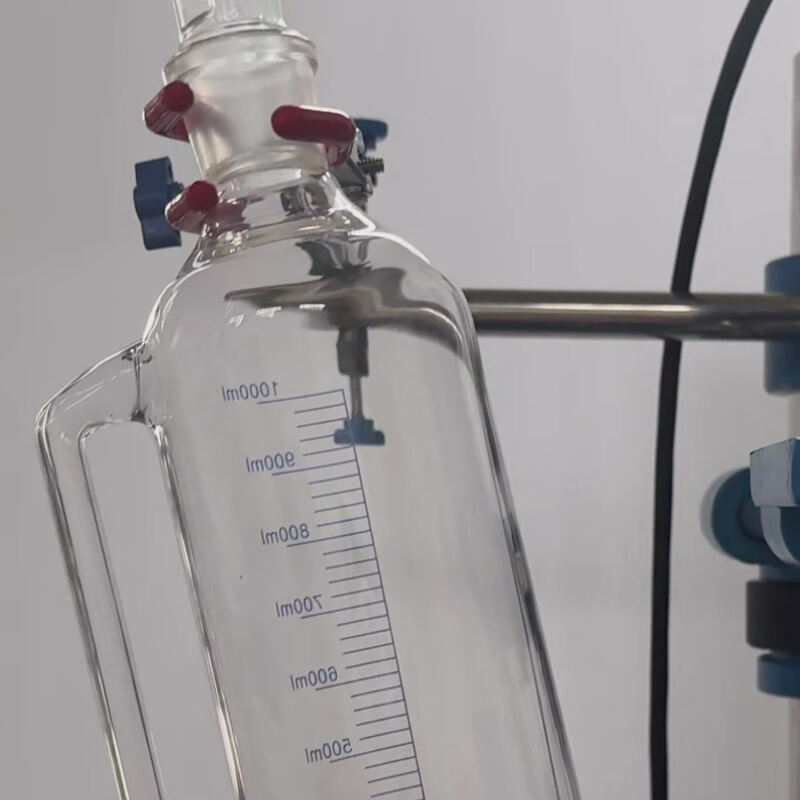

stainless steel reactor with stirrer

The stainless steel reactor with stirrer is a robust and versatile piece of equipment designed for a variety of industrial processes. Its main function is to facilitate chemical reactions at controlled temperatures and pressures, making it essential in pharmaceuticals, biotechnology, and chemical manufacturing. The reactor features a high-grade stainless steel construction, which ensures durability and resistance to corrosion. The integrated stirrer promotes uniform mixing, enhancing the efficiency of the reaction process. Technological features include precise temperature control systems, pressure regulation, and a range of safety mechanisms to protect both the operators and the integrity of the process. Applications span from small-scale R&D to large-scale production, making this reactor a cornerstone of modern industrial operations.