stainless steel continuous reactor

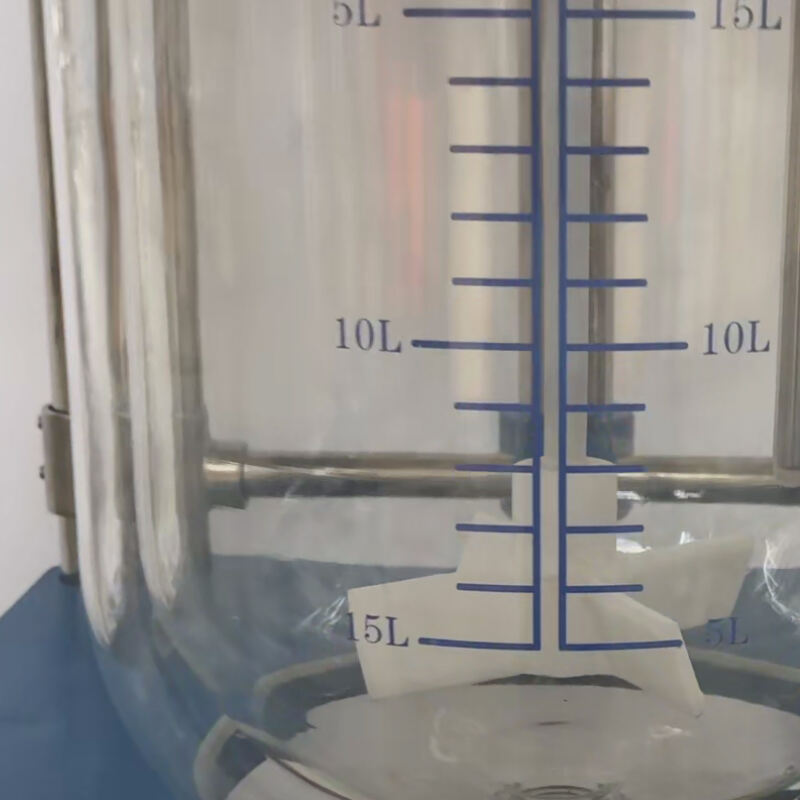

The stainless steel continuous reactor is a cutting-edge piece of equipment designed for efficient and continuous chemical processing. Its main functions include mixing, blending, reacting, and heating of substances in a controlled environment, which is essential for the production of various chemicals, pharmaceuticals, and food products. Technological features of this reactor include a robust stainless steel construction for durability and resistance to corrosion, advanced temperature control systems for precise process regulation, and a unique design that facilitates easy cleaning and maintenance. The applications of the stainless steel continuous reactor span across industries such as pharmaceuticals, fine chemicals, petrochemicals, and biochemistry, making it an indispensable tool for researchers and manufacturers alike.