chemical stainless steel reactor

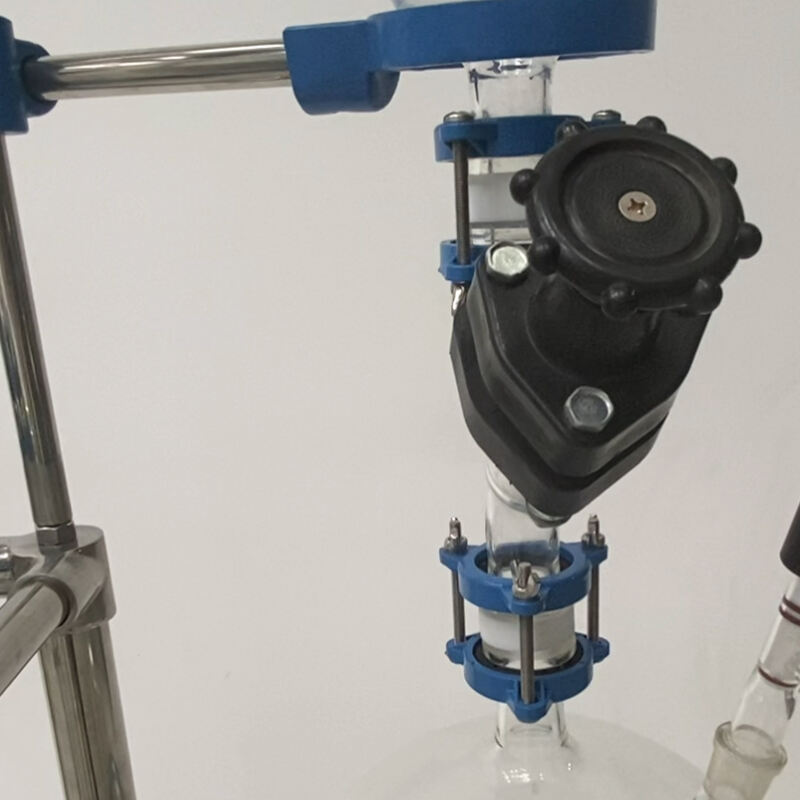

The chemical stainless steel reactor is a precision-engineered vessel designed to facilitate a variety of chemical processes. Its main functions include mixing, blending, heating, cooling, and reactions of chemical substances. Constructed from high-grade stainless steel, this reactor boasts excellent corrosion resistance, making it ideal for handling aggressive and high-purity chemicals. Technological features such as a jacketed design for even temperature distribution and an advanced impeller system for efficient mixing enhance its performance. The applications of the chemical stainless steel reactor are vast, including pharmaceutical production, petrochemical processing, and the manufacturing of food and beverage products. With its robust construction and precise controls, it ensures consistent and reliable operation in demanding industrial environments.