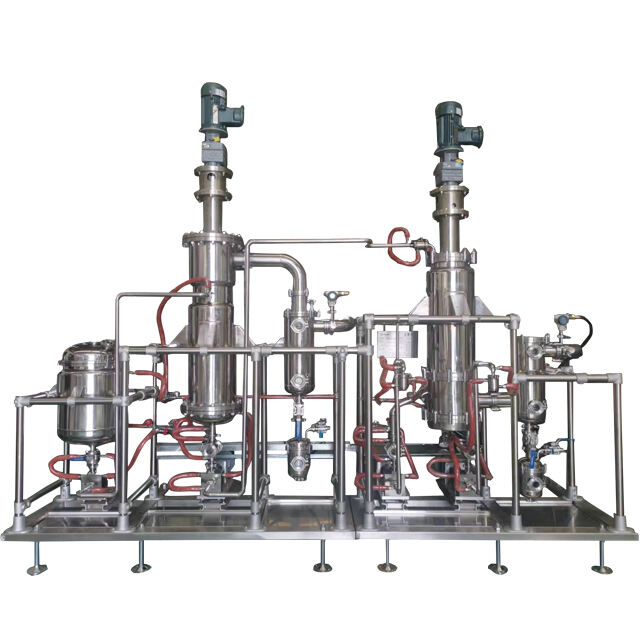

молекулна дестилация на кратка траектория

Кратката молекулярна дестилация е иновативна технология за разделяне, която предлага безпрецедентна ефективност при обработката на термочувствителни и вискозни материали. Техниката включва тънък филм от веществото, което се дестилира, който се нагрява, за да се изпарят по-волатилните компоненти. Основните функции на кратката молекулярна дестилация включват пречистване, концентрация и разделяне на сложни смеси, като същевременно се запазва целостта на качеството на продукта. Технологични характеристики като кратка дължина на пътя между нагревателната повърхност и кондензатора, заедно с ниско работно налягане, предотвратяват деградацията и осигуряват висока чистота на крайния продукт. Тя намира приложение в различни индустрии, включително фармацевтичната, хранителната и козметичната, където обработката на чувствителни материали е от съществено значение.