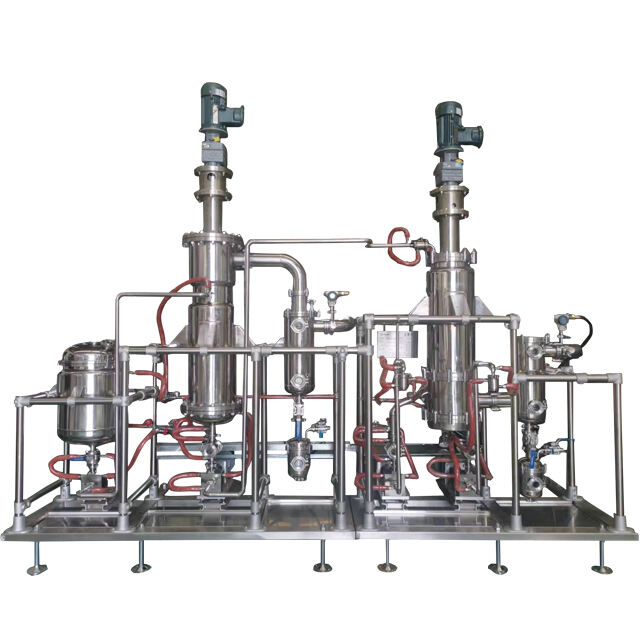

A termékenység maximalizálása acéllapiszállító rostmentes acélreaktorokkal

Bevezetés Az acélból készült, külsőburokban lévő reaktorok kritikus szerepet játszanak számos olyan ipari környezetben, ahol a pontos hőmérséklet-szabályozás rendkívül fontos. Vegyi üzemek, gyógyszeripari vállalatok, sőt még élelmiszer-feldolgozó üzemek is ezekre az egységekre támaszkodnak, mivel...

További megtekintése