Jacketed Glass Reactors: A Comprehensive Guide for Buyers

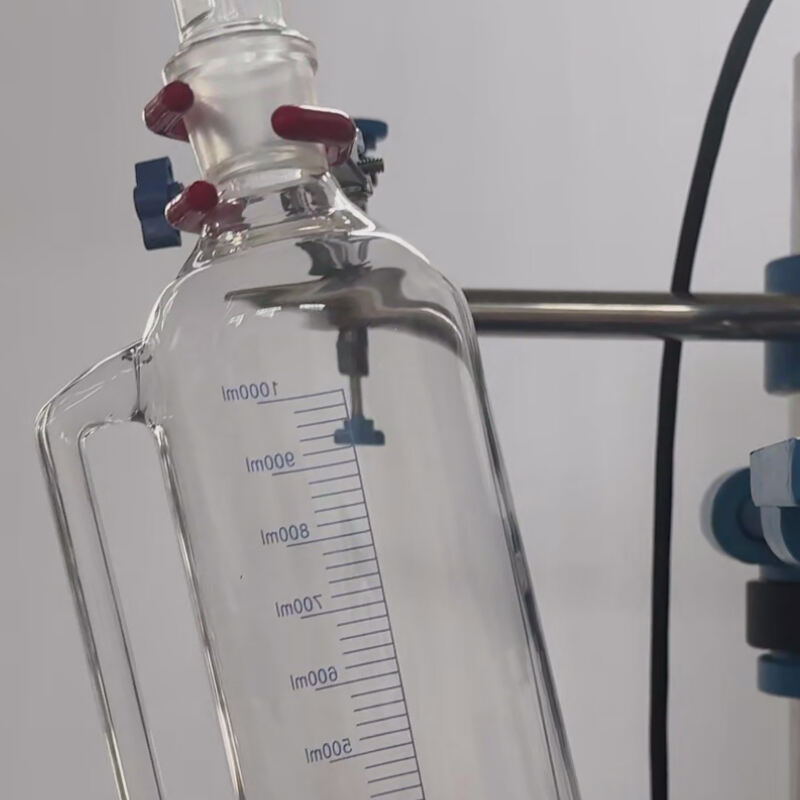

Jacketed glass reactors are specialized vessels designed for precise temperature control during chemical reactions. Industries rely on these reactors to ensure consistent results in processes like synthesis and crystallization. Their transparent desi...

View More